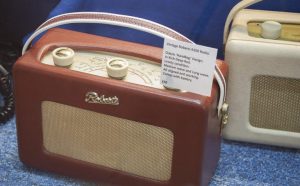

Lots of new stock available in the shop.

As you can see from the new header photograph, and the pictures below, I have lots of new stock in the window at 27 new Street.

Come in and have a look.

A blog about things that I have for sale.

Lots of new stock available in the shop.

As you can see from the new header photograph, and the pictures below, I have lots of new stock in the window at 27 new Street.

Come in and have a look.

A Belgian telephone. A customer came in and asked if I could rewire a telephone. I replied ‘yes, that’s fine’ then she pulled a somewhat bedraggled heavy Belgian telephone out of her bag.

It’s not something you see too often in the UK so I was not expecting that, however, she left it with me and I got to work.

Above – And here is the result of some careful polishing and rewiring/standardising for the UK phone network. It is all metal, apart from the handset, which is bakelite, so is a hefty little monster and it has a fold up brass handle to carry it around, very nice. All in all, quite a pretty little gadget.

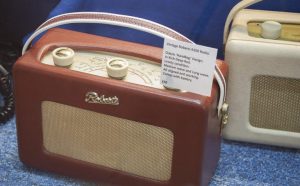

This one was in a bit of a state. Apart from being dirty, it just was worn out. Things needed to be engineered to get it back on it’s feet.

First thing to do was strip it down to it’s component parts and give it a good scrub.

Next step was to repair the cassette deck, this needed new belts, new head, new pinch roller and an idler.

The idler was the only par that I could not get, so I machined up one on the lathe.

Above – worn head.

Above, the cassette deck, a work in progress at this point.

Above – And here it is looking resplendent in the window of the shop, ready to go off to someone who will appreciate it as much as I do. 😀

Very tatty condition and missing it’s brass inserts for the knobs.

And after extensive restoration…

All happy again with one of my hand made carrying handles. 🙂

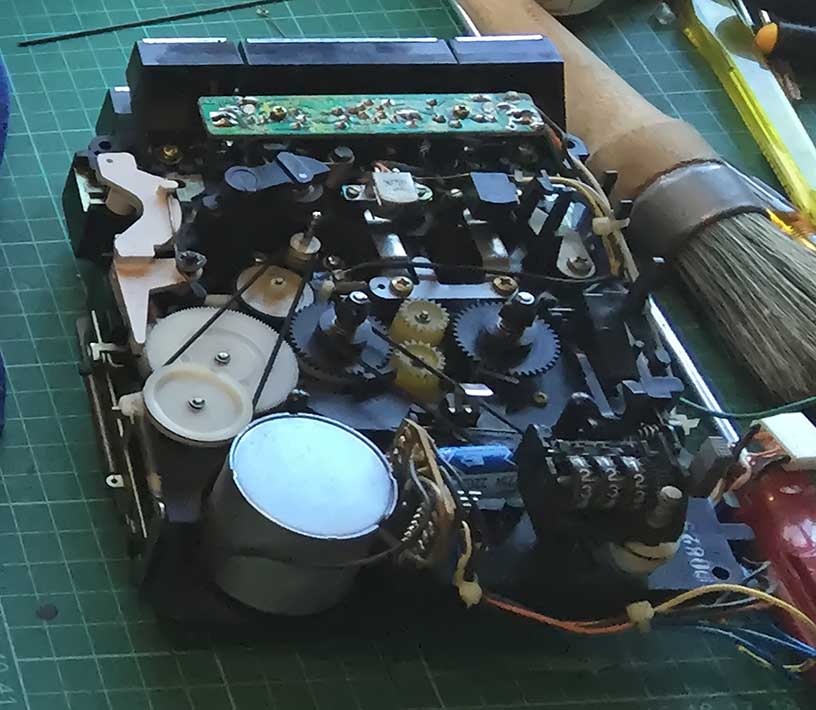

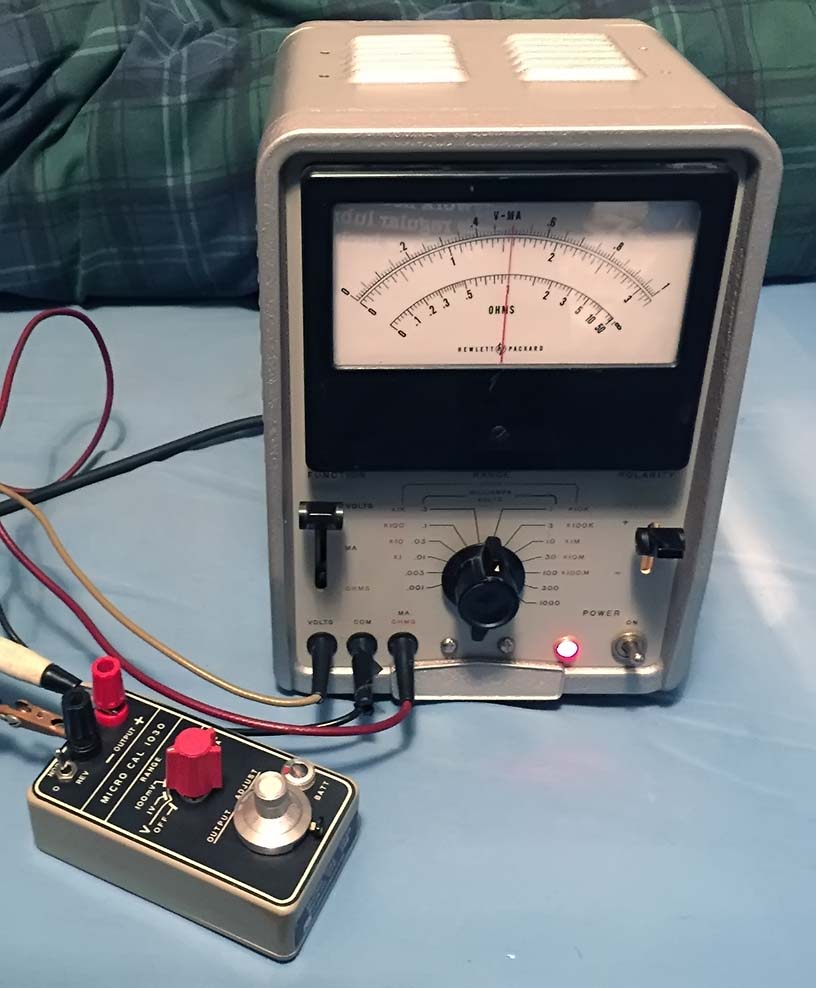

So, this wasn’t exactly what I ordered, it should be a signal generator. However, since it’s going to cost too much to post back to America, I’ve been allowed to keep it.

So let’s see if I can turn this poor old thing back into a piece of test equipment again.

New splash of paint, and a full refurbishment later and this little beastie is now looking good again.

After a read of the manual and a thorough calibration, all is well again. 🙂

If you’re looking for a stellar condition 706 telephone, we now have a range of many colours. Also available are the 746 range and some trim phones too.

In a bit of a sorry state this one, fingers crossed we can make it look good again.

Refurbish time…

Final result. Guest appearance, a two-tone Trimphone 🙂

Well, it’s sort of on the bench, and on the floor and all over the place. 🙂

After a full strip down, clean and realigning/re-oiling it is now running beautifully again.

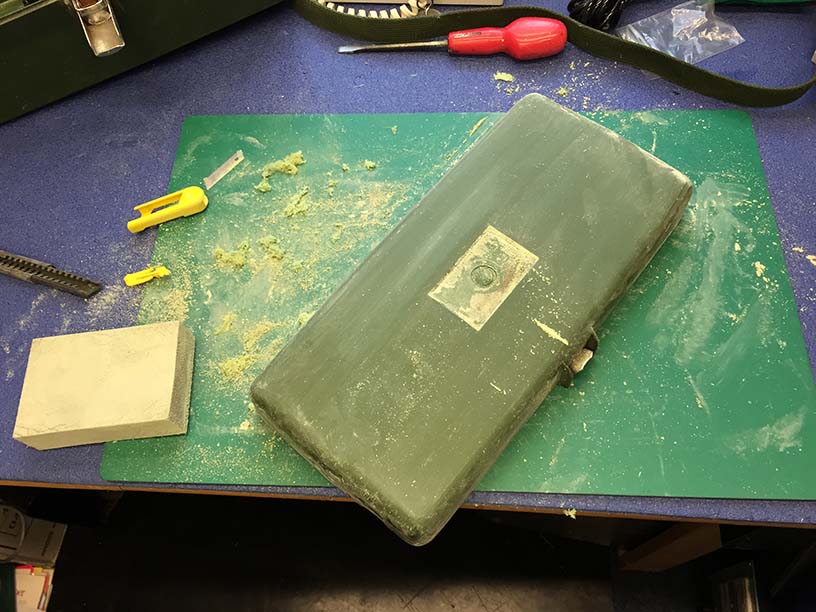

Both the base and the lid were in quite poor condition.

but after a light sanding and waxing with beeswax it is now looking lovely again.

Fed up with not having a decient controller for the Vectrex I had a look through the bits and bobs from when we were using tablet sized boxes at Panasonic and found some enclosures that might just do….

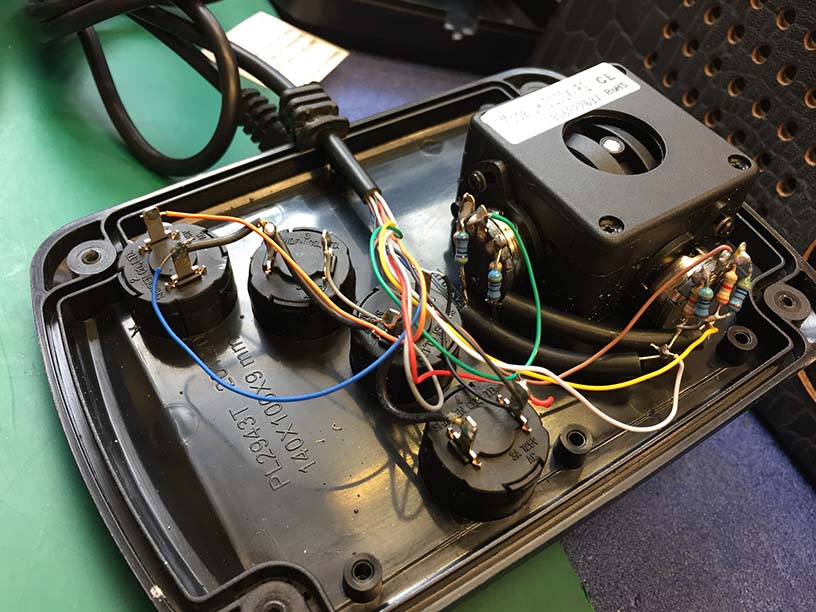

Here’s what it looks like inside, quite simple, all that is needed is a few dropper resisters, a potentiometer and extension cable from China, and some small arcade buttons.

They’re a bit untidy at the moment, but I will sort that out at a later date, at the moment I just want to try things out make sure everything is okay.

So far, they work really well and are very precise. However, the overlays on the top are a bit fragile., so I will have to come up with something a bit stronger but it’s good enough for now.

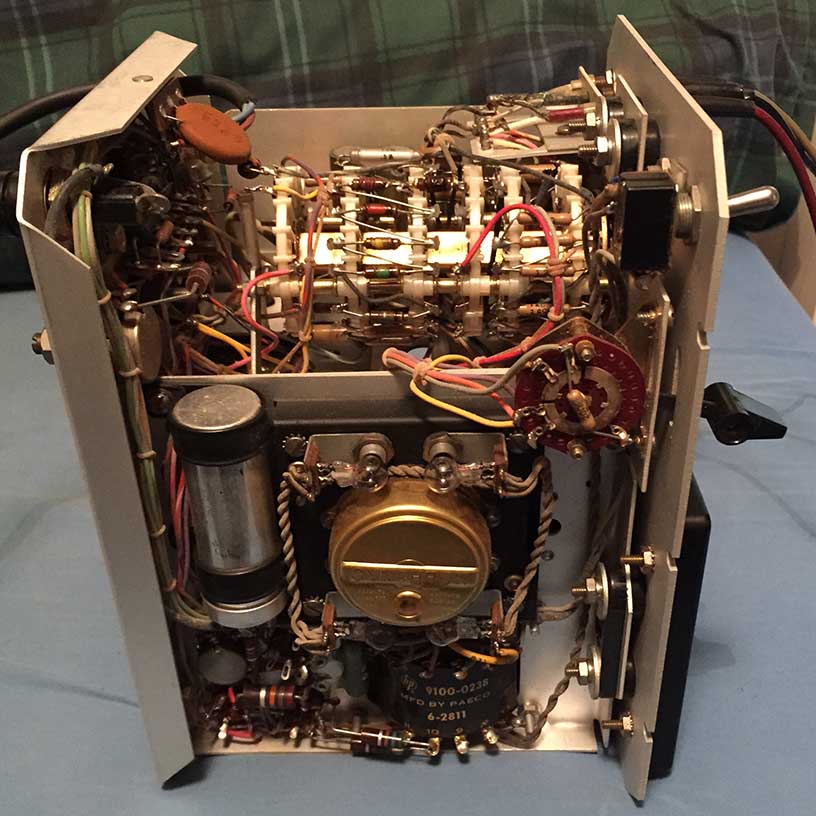

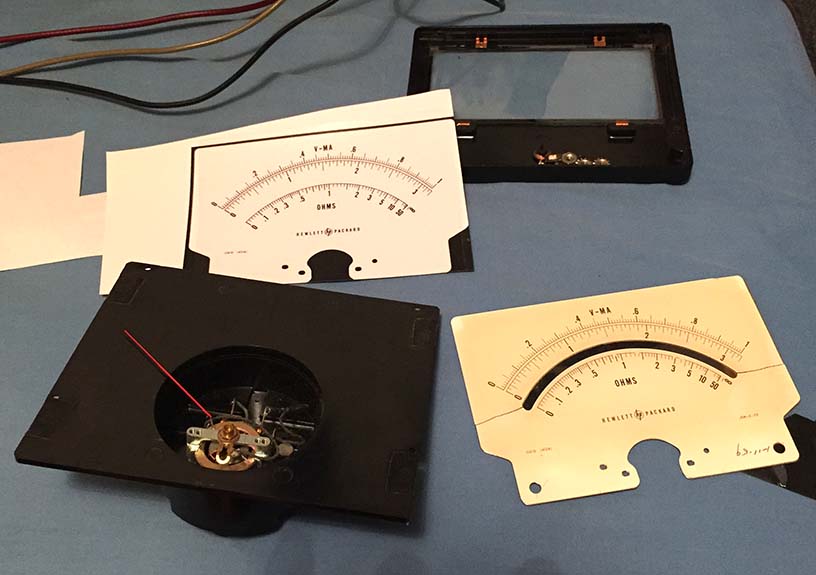

Apologies, as this is a really long post. However if you want or have one of these units it might actually save you a lot of hard work.

I got this quite some time ago, and it was about time to repair it ready for use.

So, first things first, the original mains lead had snapped at the plug end internally and the wires have turned hard, so it won’t be long before they break or short out internally causing all sorts of unpleasantness. I decided to upgrade the socket to a somewhat more modern design Looking at the service diagram the old socket has filter coils and capacitors moulded into it.Digging about in the spares box I found an old filter capacitor set from a computer power supply unit which had the same specifications as the old old one. I grafted this on to the socket and connected all of the outputs to their respective places, the only thing to do now was to very carefully remove a section of metal and file it down so it looked neat and tidy.

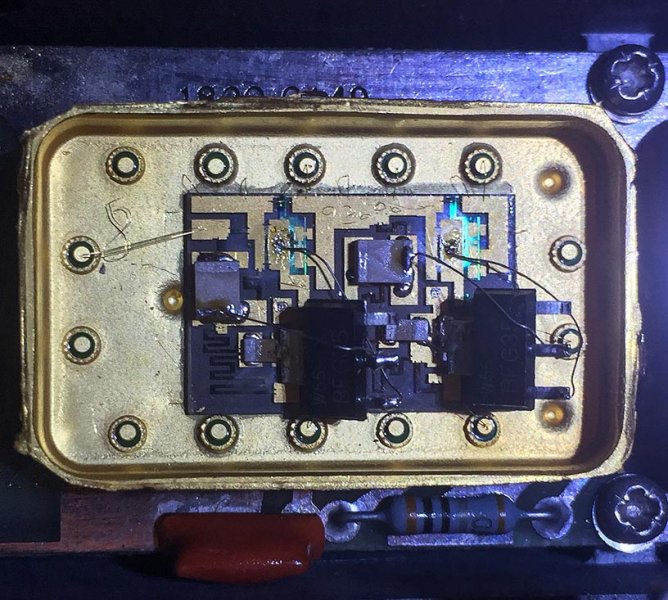

Knowing that the unit powered up to some extent I tested the output for a signal, nothing. Luckily on this model it only has three hybrid ic’s and you can swap them around for each other temporarily for fault finding purposes. On doing so I got a strong signal but was unable to alter frequency. All of this meant one of the output preamplifier hybrids was faulty. So all got put back to their original places and I powered up the oscilloscope. The top preamplifier had lots of signal in but not much out.

If it was the final power amp I would have probably just bought one of this gentleman’s fine replacement examples, but this was the preamplifier, so I decided to take the lid off carefully and have a look inside to see if there was anything obvious. Under the microscope you could just see that the transistors were looking a little sad for themselves, which was confirmed by very carefully testing with a meter confirming that the emitters were almost open circuit. The plan was to solder compatible transistors onto the hybrid directly with fine wires for base and emitters to the appropriate places. Borrowing from his research the BFE35 transistors seemed a pretty good match for what was needed, so I ordered a few to experiment with.

Using a fine pair of tweezers and a micro tip soldering iron I soldered on the new parts very carefully, so as not to damage anything else and powered up. Instant signal

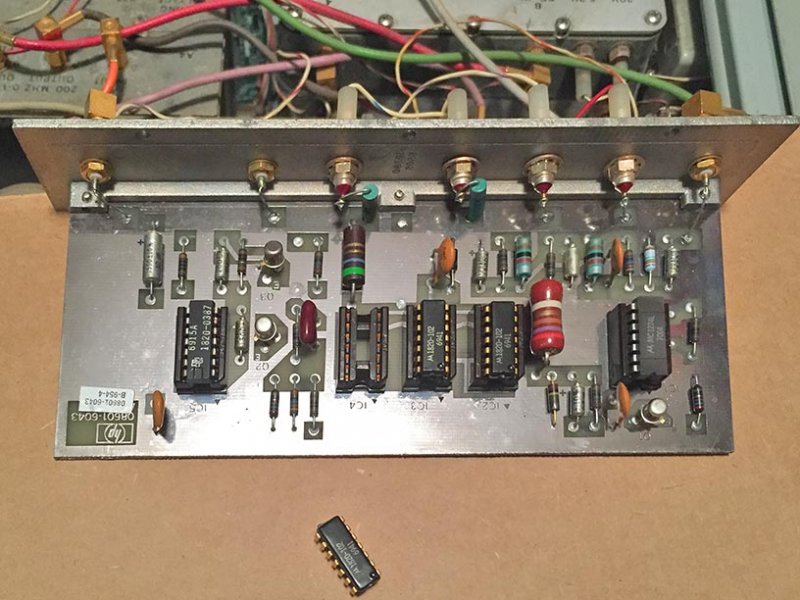

After grinning like a muppet for a while I discovered I was not completely done yet. Whilst it worked perfectly on the lower frequency scale, it had no signal on the upper scale. So, to rule out any spurious problems with switches I spent the next hour cleaning up all of the contacts on all of the switches and getting all of the dust out. Now it was much nicer to use, but the upper scale still didn’t work. Grabbing the service manual and printing out the various flow charts and diagrams, it was obvious HP don’t like engineers very much. The manual is a bit of a mess, and bits of it was scattered throughout the entire manual with no logic behind anything. However after working out how they wanted you to service the item things began to fall into place. First port of call was the divider assembly, there is a perfectly good signal on the 0-11 scale, but from the 11 to 110 MHz range there was absolutely nothing. After carefully removing the divider board and checking the signals on the chips something didn’t add up. One of the chips had a random signal on its output, and even then it was barely there.

Naturally on checking, none of these chips are available any more, partly because they’re HP branded versions of Motorola’s chips, and also the fact that Motorola don’t make them any more anyway. Thankfully some kind soul had put an equivalent table for the chips online which led me to find an equivalent to the faulty one which was numbered 1820–0102 and its replacement is an MC1013p. I managed to find someone selling some ‘new old stock’ of these online and quickly ordered up a few.

Now is the new chip installed and fitted the upper frequency was now reinstated. Another small dance ensued

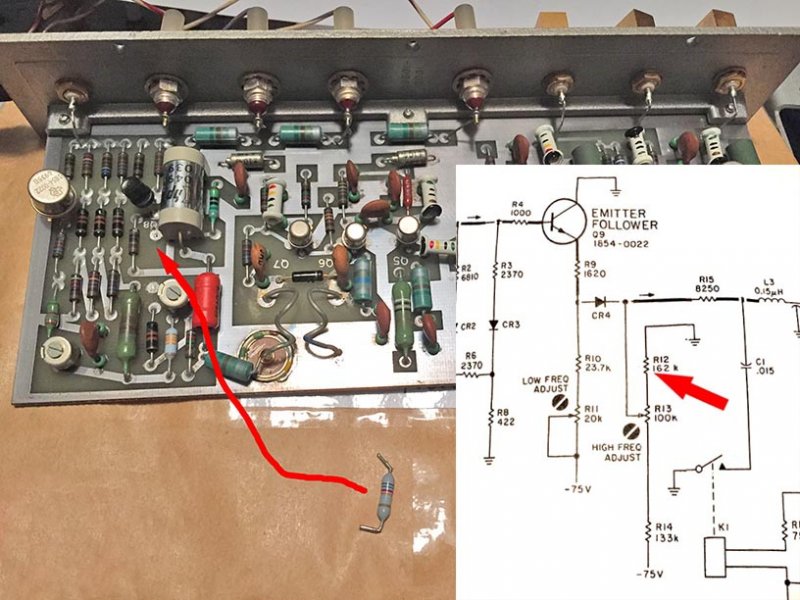

that was, until I tried to use the sweep function, The signal went dead. I was beginning to believe that this was made up of an entire bunch of these units that were all faulty and I,d ended up with all the broken bits from halfway around the planet. When the sweeper was switched from carrier wave to sweep the signal would die. Not quite sure where I was to actually go next I decided to work through the alignment procedure on each one of the packs to see if anything was grossly out of alignment. First couple of packs seemed to be okay, those being the power supply, and the crystal oscillator adjustments, I gave him a bit of a tweak whilst I was there to get them spot on. Next up was the voltage tuned oscillator, the first thing I noticed was when you disconnected the lead to do the initial adjustment, the signal went dead. So I removed this board and went around testing voltages around the various areas. Something didn’t seem right, there was 75V on everything and whatever frequencies were there, were all over the place. so obviously something was wrong here to, on closer inspection like with all the other boards this one didn’t seem to match anything to do with the serial number, so was yet another of somebody’s broken lineup of products.

After a little while I managed to find a open resistor (shown above) and on the replacement of this and a quick set up of the now very grossly out of adjustment oscillator, I finally had a working piece of test equipment on every single setting.

Phew, this all took just about a week to achieve between various other jobs that came in needing to be done, But at least now I have a very nice piece of test equipment that I can use to set up the IF stages of radios. You can actually just sit a radio on top of the unit and it gives off a enough RF to hear the broadcast tuning past the radio’s tuned point. If you see what I mean.

So that’s it, I will probably refurbish the cabinet of this unit at some point, but for the meantime I’m just going to enjoy using it.

All the best out there in radio land, Ast.