So, instead of a shop, all the bits and bobs that get repaired are now being sold on eBay, but you can still buy them direct if you want to, just give me a call.

You can find my eBay shop here- https://www.ebay.co.uk/usr/panasonic_bloke

A blog about things that I have for sale.

So, instead of a shop, all the bits and bobs that get repaired are now being sold on eBay, but you can still buy them direct if you want to, just give me a call.

You can find my eBay shop here- https://www.ebay.co.uk/usr/panasonic_bloke

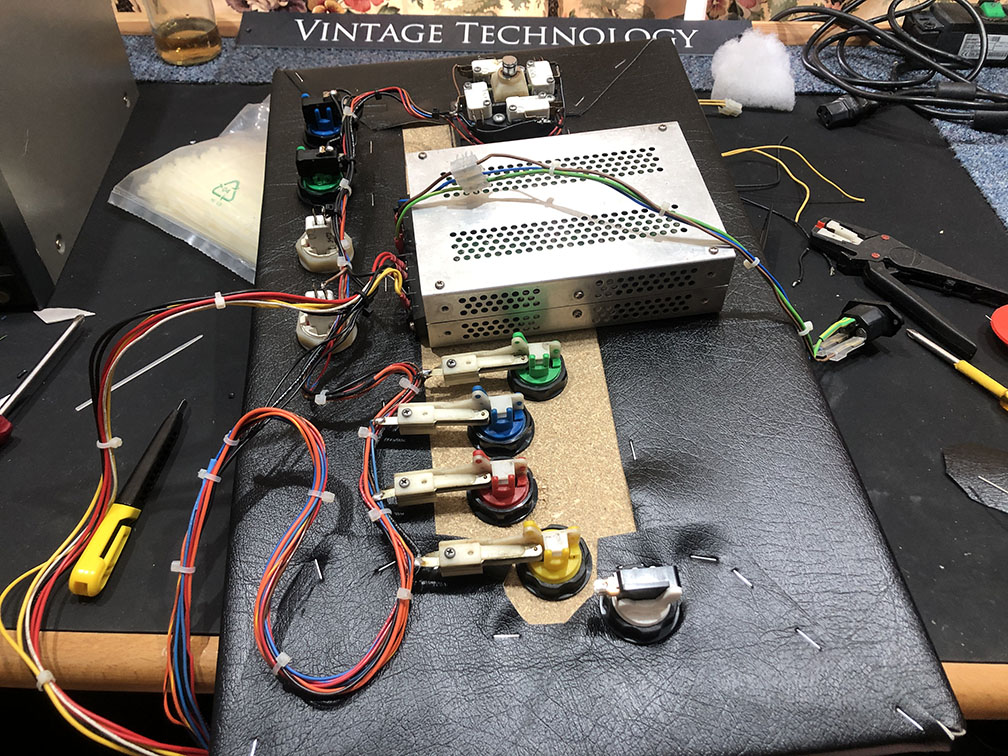

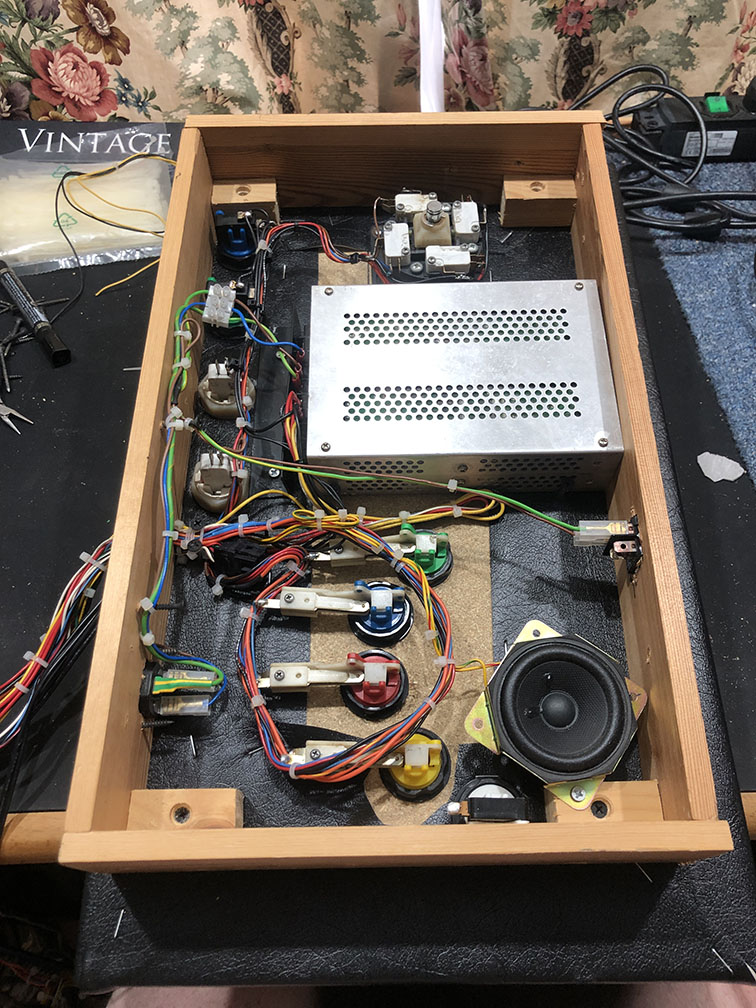

For the last few days I’ve been working on some arcade circuit boards, and since I didn’t have anything to physically power them up separately, I decided to put something together, out of bits and pieces I had lying about, which is called called a “super gun”. Not sure quite why it’s called that but there you go.

So far I’ve go the Space intruder board working, Pacman board working, and the biggest headache so far has been the MVS Multi-game system, which had a leaky battery that destroyed a whole load of tracks. A sense of relief when it finally powered up working was immense, as these are now extremely rare.

I’ll save it all up for Saturday mornings when I can have a break, and veg out playing arcade games.

The new workshop got finally completed last week, and I have been sorting through bits and bobs and putting things on shelves since then.

Here’s a handful of photographs.

So, give us a shout, our new address is not far from the Saltash Bridge. See you soon.

Find it here- https://www.youtube.com/watch?v=W_qcM_m_Hls

I always fancied giving one of these a go, having used the real thing at Sony and Panasonic and failing to bring them home when I left, forgetting that I paid for them in the first place, there’s been a few instances where I’ve needed to check the take-up tension on a tape deck.

So, armed with a jar of various springs and an old cassette I set about to make my own.

Obviously it’s not going to be a fully rotational unit, however, it will measure perfectly fine for a few seconds before the auto stop cuts in.

Here are the results.

Quite pleased with the result and it’s calibrated to a Tentelometer, so it’s quite accurate.

Well, that’s it. Last day open for the shop. Bit of an anticlimax, but to be honest, we haven’t seen a customer in three months, so it couldn’t keep going on forever. Will now be selling what’s left online, so keep an eye out for that update.

Anyway, at least all the test equipment will be in one place, which will make things a bit easier.

Radio-Shack Tandy Realistic AM Radio.

This little radio was donated to the shop, about a year ago, and I just found it when I was tidying up. I decided that would be a good idea to have a quick look to see if it was anything simple.

After replacing a few capacitors that had very much leaked, it still didn’t have any sound. Can you possibly see why-

Yes, that’s right the speaker wire had corroded and broken off. Looking at the other side it didn’t look too bad, so I thought I would attempt a very basic repair, that of soldering a wire to the working side of the speaker, poke it through and solder the flexible wire on the other side.

Not perfect, but pretty good, it’s structurally sound and also it works. Another little radio saved from doom.

This video is about upgrading the power supplies to a more reliable switch mode 5 V regulator, and buffering the video output, through the existing socket on the back, with a transistor for a brighter picture.

Enjoy. 🙂

Today, i’ll be showing a re-skimming of the commutator of a Tamiya technigold motor and a quick demo of a spring tensionometer on an LRP motor as well.

Enjoy.

Just a quick video showing how to erase tapes properly.

In a funny sort of way I still like cassettes. When I started out recording stuff, I guess we all bought the cheapest nastiest cassettes we could find (usually from Smiths or the local CO-OP), and then were surprised that they didn’t work very well and chewed up, plus they sounded terrible. Now, I’m able to record on chrome tapes and metal tapes that sound better than CD. Still, I’d napalm those crappy cassette’s, If it wasn’t for the fact that they’re so valuable now. 😀